typical charpy impact test results|charpy impact tester : fabrication A Charpy test along the transverse axis results in potential cracks along the longitudinal axis. The cracks develop (should the Charpy test fail) perpendicular to the direction of the impact test plane. Thus, a Charpy test along the transverse axis results in the safest test. These factors are considered in Chapter 3. WEBPara assistir qualquer filme ou série gay asiático basta entrar no nosso novo site.LINK DO SITE - https://pifansubs.com

{plog:ftitle_list}

Resultado da 17 de dez. de 2010 · Find the latest UFC event schedule, watch information, fight cards, start times, and broadcast details.

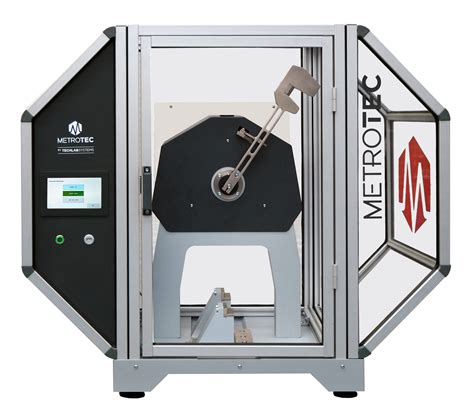

charpy impact tester

Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy . Results of impact testing are determined by three methods. In the first method, they can be read directly from the testing equipment (in joules). . Instrumentation for a typical Charpy impact testing system includes an instrumented striker, a dynamic transducer amplifier, a signal-recording and display system, and a velocity-measuring device .The results of this study reveal that the properties of the run-off plate were not diluted toward the base metal and the Charpy impact value at the weld end was up to 48% greater than the impact .

The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point .

A Charpy test along the transverse axis results in potential cracks along the longitudinal axis. The cracks develop (should the Charpy test fail) perpendicular to the direction of the impact test plane. Thus, a Charpy test along the transverse axis results in the safest test. These factors are considered in Chapter 3.

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). This video shows how a typical Charpy impact test is performed: Charpy Impact Test on Youtube, by MaterialsScience2000. . These properties and formulas are integral to analyzing and interpreting impact and drop testing results, providing insight into a material's ability to withstand dynamic forces and shocks.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

computing uncertainty. We assume the reader is somewhat familiar with the Charpy machine verifi cation program administered by the National Institute of Standards and Technology. Keywords: absorbed energy; Charpy V-notch; impact test; pendulum impact test; uncertainty; verifi cation testing 1. Introduction The absorbed energy of a test .

The Charpy impact test relies on the potential energy of a . Impact velocities for typical Charpy apparatus are in the range 3≤v≤6 m/s [31]. The low end of this range corresponds with . Charpy impact energy results for normal concrete [40], UHPC [38 ,43445152], and other advanced cementitious composites [53,54]. The results of these .A database of instrumented impact test results was generated from four line pipe steels, two quenched 1 Contribution of NIST, . Typical thickness values for sub-size Charpy specimens (SCVN) are 7.5 mm (3/4-size), 6.67 mm (2/3-size), 5 mm (1/2-size), and 2.5 mm (1/4-size). An alternative approach is to reduce both cross section

Specimens with different widths and side grooves are tested. The finite element model of Charpy impact was established by ABAQUS software. Use test results and simulation results to verify each other.%PDF-1.5 %âãÏÓ 1381 0 obj > endobj 1397 0 obj >/Filter/FlateDecode/ID[99F09C433BA3E74FAFD6B5679B801655>10D0DE9B1FDC084D81D228EB77CDEE20>]/Index[1381 42]/Info 1380 .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.Charpy Impact Test. Full Code MET0102215. Module Type. E-learning. Description What you will learn - Explain an Introduction to Charpy testing, fracture surface appearance, and the history of brittle fractures; . - Interpret the effects of a notch, and typical Charpy test results; - Identify the triaxial tension, Charpy testing equipment, and .

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) . InCharpy testing,consideration of shearlipsis importantwhen measuring twoof thethree typical results of an impact test: lateral expansion and shear fracture appearance. Lateral expansion is a measure of ductility that

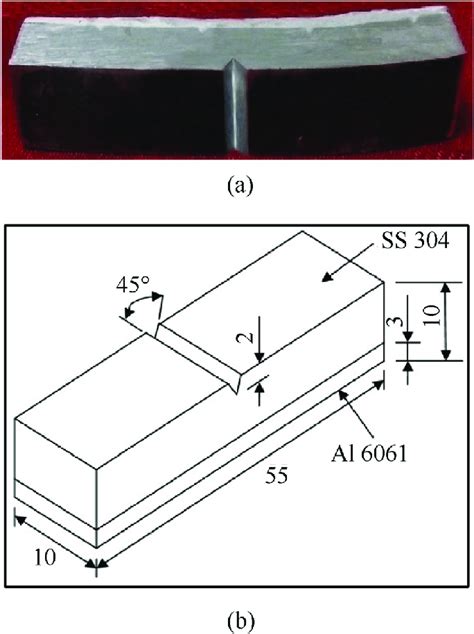

charpy impact test sample dimensions

The customer shall use its own independent skill and expertise in the evaluation of the resin. product to determine suitability for a particular application and accepts the results at its sole risk. CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum.The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to calculate the impact energy in J/m2 by dividing the joule value by the sample's cross-sectional area at the sample notch.

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

steel plate would pass a Charpy impact test has been developed. This was done to prevent testing material that would not pass the required Charpy test, without having to sample the plate for grain size. Avoiding testing plates that would not pass would preclude loss of material and time, resulting in savings for the com- pany. To interpret Charpy impact test results effectively, it is essential to understand the key parameters and their significance. According to leading websites such as “twi-global.com,” “azom.com,” and “asminternational.org,” the following aspects should be considered: . Energy Range: A typical Charpy impact tester should cover energy .Download scientific diagram | Impact test results for aluminium specimen from publication: Evaluation of Fracture Energy of Aluminium Alloy 1050-F and Carbon Steel EN -3 (~1015) 0.15% C at . A typical columnar grain microstructure along the build direction can be observed. Fine dendrites (around 300 nm thickness measured from SEM images) can be distinguished from OM observations. . First, the best conditions for surface finishing and then the Charpy impact test results from one reference batch (defect-free) and one defective .

Figure 2-1: Charpy impact tester, sample positioned in anvil and general testing results. This test has been used almost exclusively with -centered-cubic (bcc) crystalline body materials. These materials show a transition from ductile to brittle behavior with temperature (Figure 2-2). This means that at low temperature the fracture energy is low.By doing this, it is possible to characterize how much energy different materials [with same size] can absorb. Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application.

Resultado da 1 de nov. de 2022 · No Reclame AQUI, empresas ruins, não .

typical charpy impact test results|charpy impact tester